It is widely accepted that wheels of around 40mm in depth are the ideal all-rounder, since they offer the best balance of low weight and aerodynamics. Those looking for the one-wheel solution - the quivver killer - would be wise then, to consider the Scope R4D. At 45mm deep, the Scope R4D disc wheels draw on the company's signature developments in the R3 Climbing and R5 Aero wheelsets.

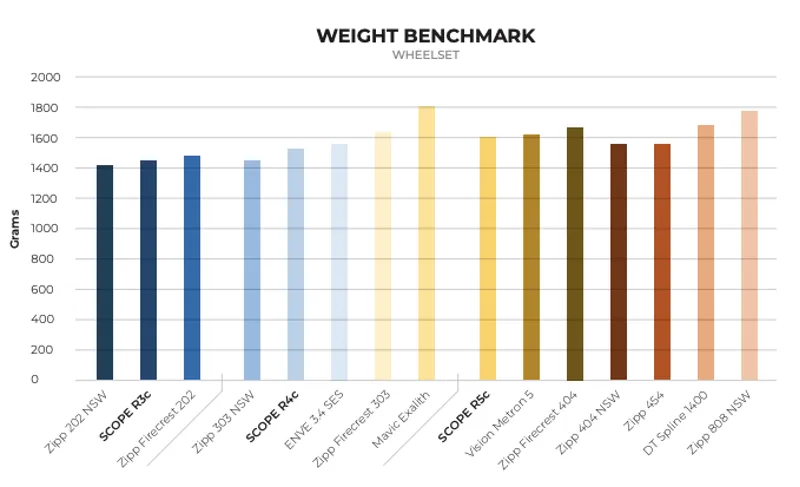

The balance of both the benchmark aerodynamics that deliver stable speed gains, and the low weight offered by Scope's proprietary Local Reinforcement Technology (LRT) at the rim (see the Buyer's Guide for more detail), are married to unrivalled lateral stiffness. These facets combine to create a wheel that delivers way above the bar on all fronts - without compromise in any aspect. Ultimately, Scope's unified approach results in a mid-section wheel that is hard to beat. At just 1557g, the R4D Disc wheels are comparable in weight to rivals that cost significantly more and that are notably more susceptible to flex. Consequently, you can be sure that your R4 wheels will transfer more of your power while remaining predictable and efficient underneath you.

Like all Scope wheels, the R4 use the company's 26mm wide, proprietary rim profile for aerodynamic advantage without the negative effects of crosswinds. By combining this profile with their own wide-flange-distance hub design, Scope can offer riders of the R4 wheel lively but confident handling in all conditions. While not as light as the dedicated climbing wheel - the R3, the R4 is an adept climber thanks to its stiffness and there are aero gains to be made for those who spend as much time riding between and coming down the hills, or who simply need one wheelset to serve wherever they ride.

All Scope wheels come Tubeless-Ready as standard and feature a relatively wide 19mm internal diameter to allow for an increase in the width of mounted tyres. In practice, a 25mm tyre measures 26mm and perfectly sits on the inner wall of the rim for an excellent aerodynamic profile, greater comfort and more confident control thanks to the enhanced contact patch of the tyre.

The Scope R4D disc wheels are finished in matt black carbon with either a matt white or matt black decal as standard. Their understated look and simple styling make them an excellent option for upgrades or builds alike and the company's range of end-caps for the hubs make fitting a doddle, regardless of the ever growing axle standards. Supplied as either Campagnolo or Shimano/Sram, an XDR Driver body is also available for those running Sram AXS or other 1x set-ups. As an added bonus, if you want to stand out from the bunch, Scope offer the option of Custom Decals at £100 per set - with 10 options in 2 finishes, there is something for everyone.

All-conquering, the Scope R4D Disc wheels are extremely stiff, high-performance, tubeless ready road wheels without limitation.

Scope Cycling are a team of Dutch engineers and designers who are all passionate cyclists. By combining technical innovation and novel approaches to development and design and by reinforcing their approach with their passion, they aim to provide riders with the best possible wheel range to enhance the rider experience.

Now, if you’ve read any background on pretty much any bike brand, new or otherwise, you will often hear a similar refrain as regards their approach. In our experience, much of what we hear is used to justify an inflated price for a product that is - to all intents and purposes - largely the same (from R&D to Production) as A N Other brand already available. This is particularly true in the Wheel market.

Our desire at 700 is to stock and present products that we feel stand above the rest. Products that are truly innovative or whose approach doesn’t simply replicate that of another product’s development. Scope are one of those brands.

Scope - unlike many other wheel brands in market - are looking for the perfect balance between aerodynamics, lightness, stiffness, and durability - rather than focussing on a single element. As such, their concise range of Carbon, tubeless-ready wheels are ideal for the real-world rider, delivering on all fronts with quite astounding results; especially given the real-world pricing.

All their products are developed in-house at facilities in Eindhoven. Considered the Dutch Silicon Valley, the city is also home to Brainport, the High-Tech campus, the University of Technology Eindhoven, and the Design Academy. With their headquarters in one of Europe’s leading high-tech areas they are able to continuously improve their products and to redefine the future of modern wheel building.

To be able to compete with industry-leading brands Scope have combined their technical background and pro cycling experience with more specific knowledge from development partners who - like them - are keen to push the boundaries of wheel building.

The result is a range of wheels that quite often resets the benchmark within the remit of the brand and encompasses all elements key to a good wheel : Aerodynamics, Lateral stiffness, weight and durability.

AERODYNAMICS

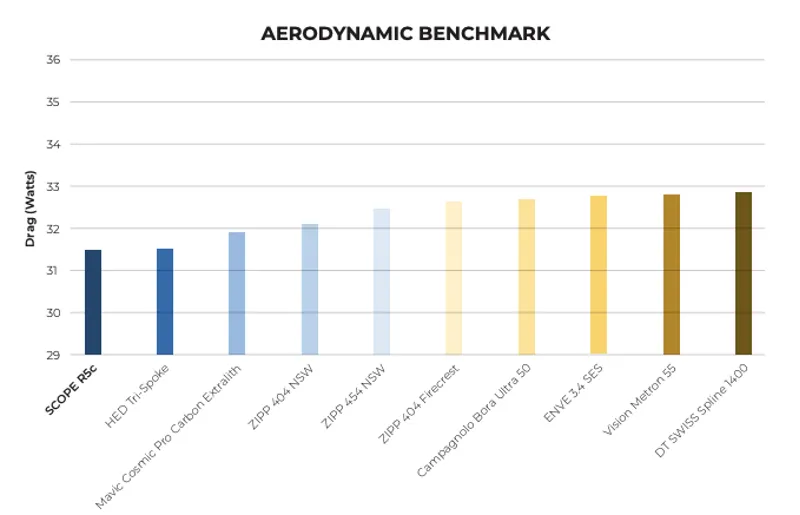

The R series of wheels deliver stable, optimised aerodynamics - the result of over a year of real-ride wind data collection, CFD analysis and uniquely, Panel Method study. The Panel Method is a surface-based flow analysis technique. It allowed Scope to exert complete control on the rim shape and define a rim shape that reduced drag without compromising side force behaviour. The result is the company’s characteristic 26mm U-shape rim profile found on each of the R3, R4, and R5 models. As part of the optimisation process, Scope designed the rim shape starting from the tyre to allow the latter to perfectly fit and to also create a smooth airfoil between the two of them. Their optimisation and validation method through CFD, 3D Printed prototypes and extensive wind tunnel and real-world testing (which factored in fork, frame and rider), is similar to inverse airfoil design, which until now - had not been applied to bicycle rims. R series wheelsets set a new benchmark for aerodynamically optimised carbon wheels.

STIFFNESS

One of the elements often overlooked by those investing in new wheels is stiffness. When discussing wheel options with clients, we are often asked about aerodynamics and weight - we are almost never asked about stiffness. The lateral stiffness of a wheel is key. Flex in a wheel leaks power, can create brake rub on rim bikes and destroys the handling of your bike - especially when you need it most : in corners, descending. Many of the top name wheels out there, whose sole focus is aerodynamics, struggle with this aspect making the investment a questionable one - especially when the price is double that of a set of Scope wheels.

Built as a system in order to create a very high lateral stiffness while keeping an equal spoke tension (critical for durability and consistent feel), Scope have optimised the flange distance of their hubs. Almost 60 percent of the lateral stiffness in a wheel is determined by the flange distance. Spoke count and thickness determines around 25% (all Scope wheels are built with Sapim CX-Ray), and the stiffness of the rim around 15%. The uniform lateral stiffness of Scope wheels is between 47-52 Nm/mm - significantly more than big name brands charging over twice the price for their wheels.

WEIGHT

After the frame, wheels make the greatest difference to your ride. The lighter the wheel, the better your bike will handle (to a point - if your bike/wheel package is too light then things get twitchy!); the faster it will accelerate, the quicker it will climb and the less it will drag you off-line in a corner.

Weight is a factor that shouldn’t be underestimated when it comes to the overall performance of a wheel. Scope’s rims for road and off-road specific wheelsets are manufactured using different types of carbon. Their hubs employ special aluminums such as AL7075 that allows for reduced weight without sacrificing durability and stiffness. Scope have also have developed Local Reinforcement Technology (LRT). This unique tech locally reinforces the rim at the spoke holes, whereas normally the entire spoke hole section is reinforced. Using this method allows weight savings of up to 40 grams per rim. A lightweight rim is important in order to achieve a more efficient utilisation of a wheel’s rotational energy. In contrast, a light yet durable hub helps to increase the lifetime of a wheel.

Handling, control and stability of your bike are factors that a wheel can have a dramatic influence on. Speed comes in part from control & confidence and Scope’s raft of developments and production technologies, combined with real-world data and experience, have driven the development of a simple-to-understand range of wheels that offer real riders tangible benefits in handling and speed - all at a price that should have the competition worried.

Scope’s range consists of 3 Road models in Disc or Rim brake configuration and one Off-road / Gravel model. The R3, R4 and R5 road models are named for their depth, all depths are priced the same and each is available with a Black or White graphic as standard. If you are looking for a semi-custom colour graphic to match your ride these are also available for a small up-charge, a nice touch to help to help you stand out in the bunch. Design partners SKF and CeramicSpeed provide the bearing options, from industry leading steel to market-defining Ceramic for both durability and performance. Simple choice and unquestionable performance - all at sensible prices - has led us to adopt Scope as our mid range wheel partner and we’re confident that no matter how you ride, Scope will have a wheelset that will meet your needs.