Scope set out to develop a range of wheels that would maximise the performance for any given style of riding. Each set features optimised aerodynamics, weight, stiffness and reliability and is created to deliver all without compromise, within the remit of the specific model. At the same time also ensuring confident braking regardless of whether you choose to ride rim or disc brakes.

A concise range makes it simple to select a wheel based on your preferred riding - mountains and climbing, all-round or all-out speed. Regardless of which wheels you choose, you can be sure that Scope's in-depth research and development will deliver a stable, lightweight, stiff and durable product that will perform optimally in the conditions you ride.

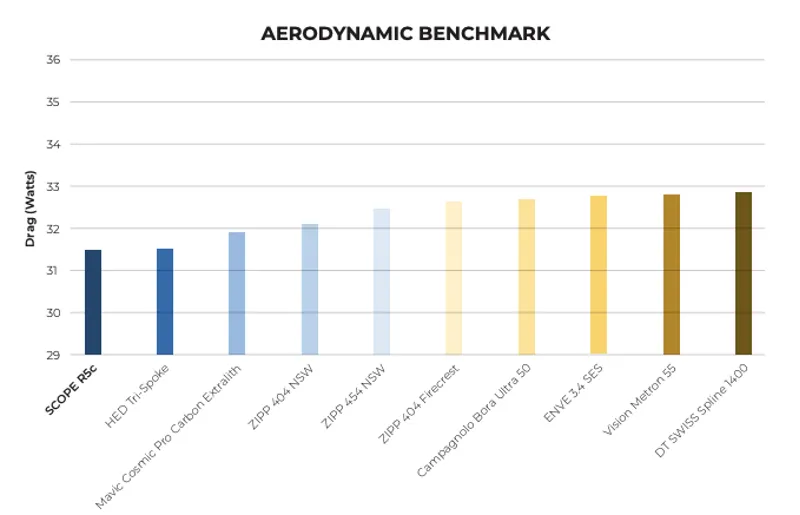

AERODYNAMICS

The R series of wheels deliver stable, optimised aerodynamics - the result of over a year of real-ride wind data collection, CFD analysis and uniquely, Panel Method study. The Panel Method is a surface-based flow analysis technique. It allowed Scope to exert complete control on the rim shape and define a rim shape that reduced drag without compromising side force behaviour. The result is the company’s characteristic 26mm U-shape rim profile found on each of the R3, R4, and R5 models. As part of the optimisation process, Scope designed the rim shape starting from the tyre to allow the latter to perfectly fit and to also create a smooth airfoil between the two of them. Their optimisation and validation method through CFD, 3D Printed prototypes and extensive wind tunnel and real-world testing (which factored in fork, frame and rider), is similar to inverse airfoil design, which until now - had not been applied to bicycle rims. R series wheelsets set a new benchmark for aerodynamically optimised carbon wheels.

STIFFNESS

One of the elements often overlooked by those investing in new wheels is stiffness. When discussing wheel options with clients, we are often asked about aerodynamics and weight - we are almost never asked about stiffness. The lateral stiffness of a wheel is key. Flex in a wheel leaks power, can create brake rub on rim bikes and destroys the handling of your bike - especially when you need it most : in corners, descending. Many of the top name wheels out there, whose sole focus is aerodynamics, struggle with this aspect making the investment a questionable one - especially when the price is double that of a set of Scope wheels.

Built as a system in order to create a very high lateral stiffness while keeping an equal spoke tension (critical for durability and consistent feel), Scope have optimised the flange distance of their hubs. Almost 60 percent of the lateral stiffness in a wheel is determined by the flange distance. Spoke count and thickness determines around 25% (all Scope wheels are built with Sapim CX-Ray), and the stiffness of the rim around 15%. The uniform lateral stiffness of Scope wheels is between 47-52 Nm/mm - significantly more than big name brands charging over twice the price for their wheels.

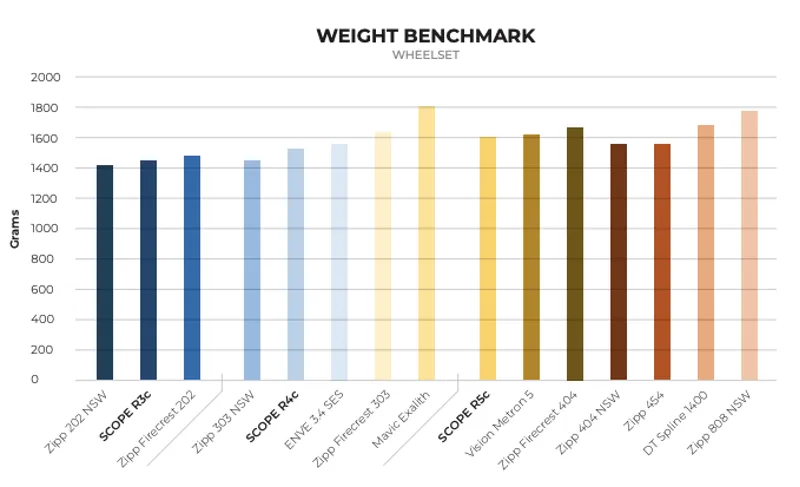

WEIGHT

After the frame, wheels make the greatest difference to your ride. The lighter the wheel, the better your bike will handle (to a point - if your bike/wheel package is too light then things get twitchy!); the faster it will accelerate, the quicker it will climb and the less it will drag you off-line in a corner.

Weight is a factor that shouldn’t be underestimated when it comes to the overall performance of a wheel. Scope’s rims for road and off-road specific wheelsets are manufactured using different types of carbon. Their hubs employ special aluminums such as AL7075 that allows for reduced weight without sacrificing durability and stiffness. Scope have also have developed Local Reinforcement Technology (LRT). This unique tech locally reinforces the rim at the spoke holes, whereas normally the entire spoke hole section is reinforced. Using this method allows weight savings of up to 40 grams per rim. A lightweight rim is important in order to achieve a more efficient utilisation of a wheel’s rotational energy. In contrast, a light yet durable hub helps to increase the lifetime of a wheel.

Despite the uptake in disc brakes, the rim brake is far from defunct and Scope users can be assured of the efficacy of the brake track when it comes to shaving off speed. Rim brake wheels can reach temperatures as high as 280oC during prolonged heavy braking. Scope's R series rim brake models have been developed using a specially formulated, proprietary resin and by using it in combination with a specific production process, Scope have ensured a consistent layup for the braking surface that can handle these high temperatures while maintaining consistent, reliable and confident braking.

Handling, control and stability of your bike are factors that a wheel can have a dramatic influence on. Speed comes in part from control & confidence and Scope’s raft of developments and production technologies, combined with real-world data and experience, have driven the development of a simple-to-understand range of wheels that offer real riders tangible benefits in handling and speed - all at a price that should have the competition worried.

Scope’s range consists of 3 Road models in Disc or Rim brake configuration and one Off-road / Gravel model. The R3, R4 and R5 road models are named for their depth, all depths are priced the same and each is available with a Black or White graphic as standard. If you are looking for a semi-custom colour graphic to match your ride these are also available for a small up-charge, a nice touch to help to help you stand out in the bunch. Design partners SKF and CeramicSpeed provide the bearing options, from industry leading steel to market-defining Ceramic - for both durability and performance.

Simple choice and unquestionable performance - all at sensible prices - has led us to adopt Scope as our mid range wheel partner and we’re confident that no matter how you ride, Scope will have a wheelset that will meet your needs.